Many people grab the nearest bit for their drill or driver without considering whether it is the right one.

What seems like a simple choice often determines whether a project runs smoothly or ends in frustration.

The question “are impact driver bits different” comes up often among both DIYers and professionals. At first glance, bits look nearly identical, but appearances can be deceiving.

Small design details can mean the difference between a clean finish and a stripped screw.

Incorrect bit use leads to problems that frustrate homeowners and contractors alike. Stripped screws, broken bits, and wasted time are common when the wrong type is chosen.

According to research, tool-related injuries account for over 135,000 emergency room visits annually in the United States 【source: https://www.cpsc.gov/Research–Statistics/NEISS-Injury-Data】.

Choosing the right bit is more than a matter of convenience; it is a matter of safety.

The global power tools market is booming, valued at more than $34 billion in 2024, with demand rising from both professionals and DIY enthusiasts 【source: https://www.statista.com/statistics/1310820/power-tools-market-value/】.

With such growth, manufacturers are investing heavily in producing stronger, longer-lasting impact-rated bits.

For anyone who owns both a drill and an impact driver, the key to efficiency lies in knowing the differences. I

mpact driver bits are designed to withstand extreme torque, while regular drill bits are not. This small distinction has a big effect on tool performance and project success.

This guide will break down those differences in detail, explain whether impact driver bits are universal, and help you decide which type is right for your tools and projects.

What Are Impact Driver Bits?

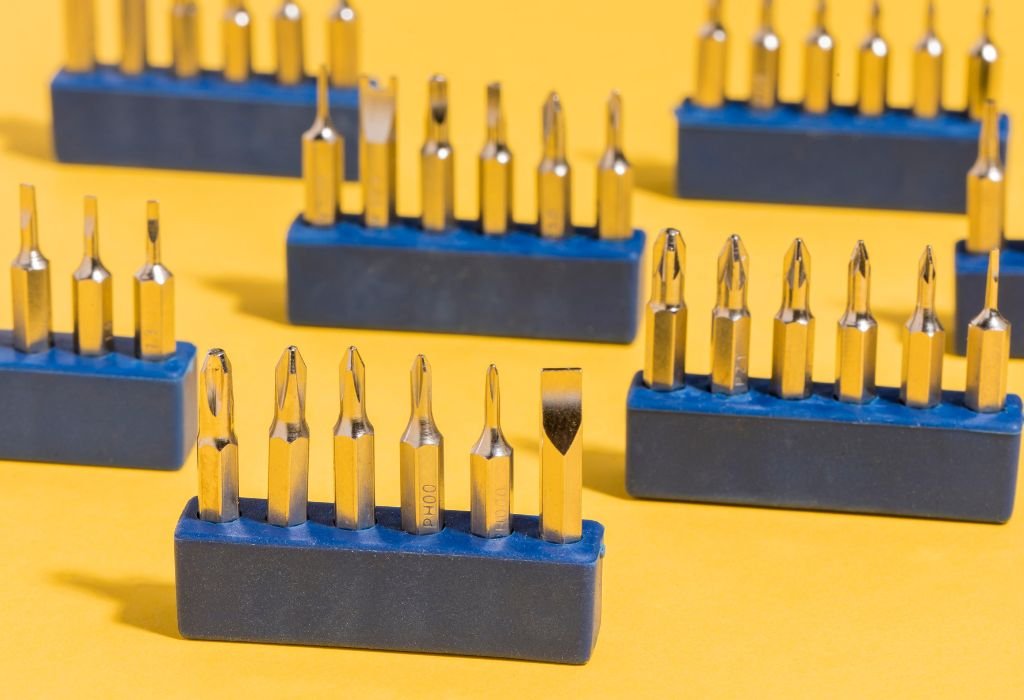

Impact driver bits are specially engineered accessories designed for use in high-torque impact drivers. They feature strong materials, torsion zones, and unique shaping to handle repetitive impacts without failing.

These bits are typically made from hardened S2 steel, which provides a balance of strength and flexibility. The torsion zone in the shaft absorbs shock, preventing sudden breakage and reducing stress on both the tool and the fastener.

Impact bits usually have a ¼-inch hex shank that locks into the driver’s chuck. This universal design ensures secure fit and prevents slippage during high-force applications.

Their magnetic tips improve precision by holding screws firmly in place. This feature reduces cam-out, where the bit slips out of the screw head under pressure.

Are impact driver bits different from drill bits?

Yes, they are designed with stronger materials and a torsion zone to handle torque that regular drill bits cannot.

Do you need impact bits for an impact driver?

Yes, standard bits may shatter or strip under repeated impacts.

What makes them stronger?

Hardened steel and shock-absorbing shaft designs give them added durability.

Can I use impact bits in a drill?

Yes, they are backward compatible with standard drills.

Drill Bits vs. Impact Driver Bits — Key Differences

The main difference between drill bits and impact driver bits lies in how they handle stress. Drill bits are made for steady rotational force, while impact bits are designed for rapid bursts of torque.

Drill bits often have round or smooth shanks, which can slip under pressure. Impact bits use hex shanks, which lock tightly and resist slipping even under extreme load.

Drill bits lack a torsion zone and can crack when exposed to repeated impacts. Impact bits flex slightly in the middle to absorb shock and prevent snapping.

Drill bits are typically cheaper because they use simpler designs and materials. Impact bits cost more upfront but last longer under heavy-duty use.

Why are drill bits cheaper?

They are made from standard steel and designed for lighter tasks.

Are impact bits more expensive?

Yes, but they last longer and reduce replacement costs.

Can drill bits handle torque?

Not effectively; they may snap or strip screws.

Is it worth paying more?

Yes, especially if you work on hardwood, metal, or construction projects.

Are Impact Driver Bits Universal?

The phrase “are impact driver bits universal” is common among new tool owners. Most impact driver bits are made with a ¼-inch hex shank, which fits nearly all impact drivers on the market.

This universal design makes them highly compatible across brands like DeWalt, Milwaukee, and Makita. However, slight tolerance differences may cause minor looseness in some tools.

While impact bits are generally universal, choosing brand-matched bits can sometimes improve fit and performance. This is especially true for heavy-duty or precision work.

Impact bits can also be used in other tools, including standard drills and screw guns, making them versatile investments.

Are impact driver bits universal across brands?

Mostly yes, but small design differences can affect the fit.

Do I need brand-specific bits?

No, but matched sets often provide better reliability.

Can I use impact bits in other tools?

Yes, they are compatible with drills and screwdrivers.

Do universal sets exist?

Yes, most major manufacturers sell universal impact bit kits.

Benefits of Using Impact Driver Bits

Impact driver bits are designed for longevity, lasting far longer than regular drill bits under heavy torque. Their shock-absorbing design reduces breakage.

Using impact-rated bits enhances safety by preventing shank fractures and screw stripping. This reduces both downtime and injury risk.

They increase efficiency by driving screws faster with less slippage. Cam-out is minimized, resulting in cleaner finishes and fewer damaged fasteners.

These bits are versatile, working in both impact drivers and regular drills. This makes them a convenient choice for professionals and DIYers alike.

Do impact bits save money long term?

Yes, by reducing replacement frequency.

Are they safer than normal bits?

Yes, they prevent accidents caused by bit failure.

Do pros always use impact bits?

Almost always for demanding applications.

Is it noticeable for DIY use?

Yes, especially when driving long screws into dense materials.

Problems with Using the Wrong Bits

Using standard drill bits in an impact driver often results in stripped screws. The high torque overwhelms the bit and ruins the fastener head.

Non-impact bits are prone to sudden shattering when subjected to repetitive impacts. This can cause dangerous flying fragments.

Incorrect bits increase wear on the tool’s motor and gears, shortening the lifespan of the driver. Stress builds up in ways the tool was not designed to handle.

Time and money are wasted on rework and replacing broken bits. Even simple projects become frustrating and costly when the wrong accessories are used.

Can using wrong bits damage the driver?

Yes, it increases motor strain.

Why do bits shatter?

They cannot absorb repeated impact energy.

Is stripped screw removal difficult?

Yes, it often requires special extractors.

Do warranties cover this damage?

Usually not if improper accessories were used.

How to Choose the Right Impact Driver Bits

Look for bits made from premium materials like hardened S2 steel. This ensures strength and resistance to torque.

Check for a torsion zone design, which allows controlled flexing and shock absorption. This prevents cracks and prolongs tool life.

Magnetic tips provide better grip on screws, reducing slippage and improving accuracy. This is essential for overhead or angled driving.

Match the bit design to your project. Wood, metal, and masonry applications all require different coatings or shapes.

What’s the best brand for impact bits?

Milwaukee, DeWalt, and Makita are widely recommended.

Should I buy sets or singles?

Sets are more cost-effective for multiple projects.

Are coated bits better?

Yes, coatings like titanium extend bit life.

Can I sharpen old bits?

Only drill bits can be sharpened, not driver bits.

Popular Brands & Reviews

DeWalt Impact Ready bits are known for durability and strong magnetic tips. They are popular among professionals who need reliable fastening.

Milwaukee Shockwave bits are praised for their toughness and ability to withstand thousands of impacts. They often last longer than competitors.

Makita Gold bits combine affordability with solid performance, making them a strong choice for DIY users. They offer a good balance between price and quality.

Customer reviews on Amazon highlight how pro-level bits reduce breakage compared to generic options. Higher upfront cost translates to better results and less frustration.

Which brand lasts longest?

Milwaukee often tops durability tests.

Are budget sets worth it?

Yes, for light DIY use, but not for daily professional work.

Do pro sets cost more?

Yes, but they deliver better long-term value.

Where to buy?

Hardware stores, Amazon, and tool specialty shops.

Future of Impact Driver Bits

New alloys and coatings are being developed to extend the life of impact bits. Titanium nitride and diamond coatings are leading examples.

Manufacturers are experimenting with advanced torsion designs for better torque absorption. These innovations improve safety and durability.

Eco-friendly production methods are becoming more common. Companies are reducing waste and energy use during bit manufacturing.

The DIY and professional tool markets are expected to grow steadily, driving continuous improvement in impact bit technology.

Will future bits last longer?

Yes, due to stronger materials and coatings.

Will prices drop?

Likely, as manufacturing scales.

Are smart bits coming?

Some prototypes include sensors for torque measurement.

Is the market growing?

Yes, powered by increased DIY and construction demand.

Conclusion

Impact driver bits are not the same as regular drill bits. They are built with torsion zones, stronger steel, and hex shanks to handle torque safely and efficiently.

Using the right bits prevents stripped screws, broken tools, and wasted money. It also ensures safer, faster, and more reliable results for any project.

When choosing impact driver bits, consider quality materials, torsion design, and brand reliability. Investing in the right accessories pays off in durability and performance.

For anyone asking “are impact driver bits different” or “are impact driver bits universal,” the answer is clear. They are different, they are better, and they are the right choice for your impact driver.

I’m John F. Nicholas, the founder, lead writer, and drill enthusiast behind 101drill.com. With years of hands-on experience in power tools and DIY projects, I created this platform to share practical knowledge, expert tips, and real-world insights to help others master the art of drilling.